Engineered for precision

Built for productivity

The Kongsberg Ultimate is the world’s most productive digital cutting table for corrugated and display production.

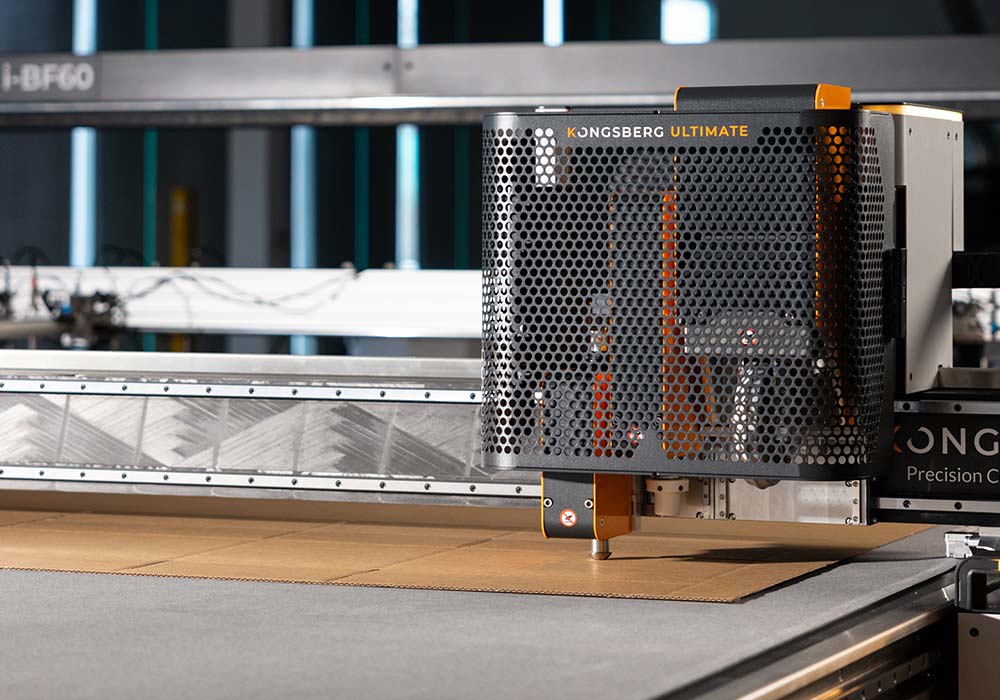

The Kongsberg Ultimate is a game changer for corrugated and display production. The expertly engineered construction of the table delivers precision results at unmatched cutting and throughput speeds: up to 2.7G acceleration and peak cutting speeds of over 165 m/min.

It represents a significant leap forward in technology, addressing the unique challenges faced by corrugated converters that handle continuous high volume multi-batch production.

And what's more: the Kongsberg Ultimate is now a multi-award-winning cutting system, after receiving a prestigious PRINTING United Alliance 2024 Pinnacle Product Award and EDP Award for Best Wide Format Cutting Solution.

Cutting, acceleration, throughput speeds, … The Kongsberg Ultimate brings unparalleled productivity with impeccable quality!

The Kongsberg Ultimate has everything on board to guarantee exceptionally precise results, even on demanding materials.

The way the Kongsberg Ultimate is designed and constructed, guarantees maximal uptime with minimal maintenance.

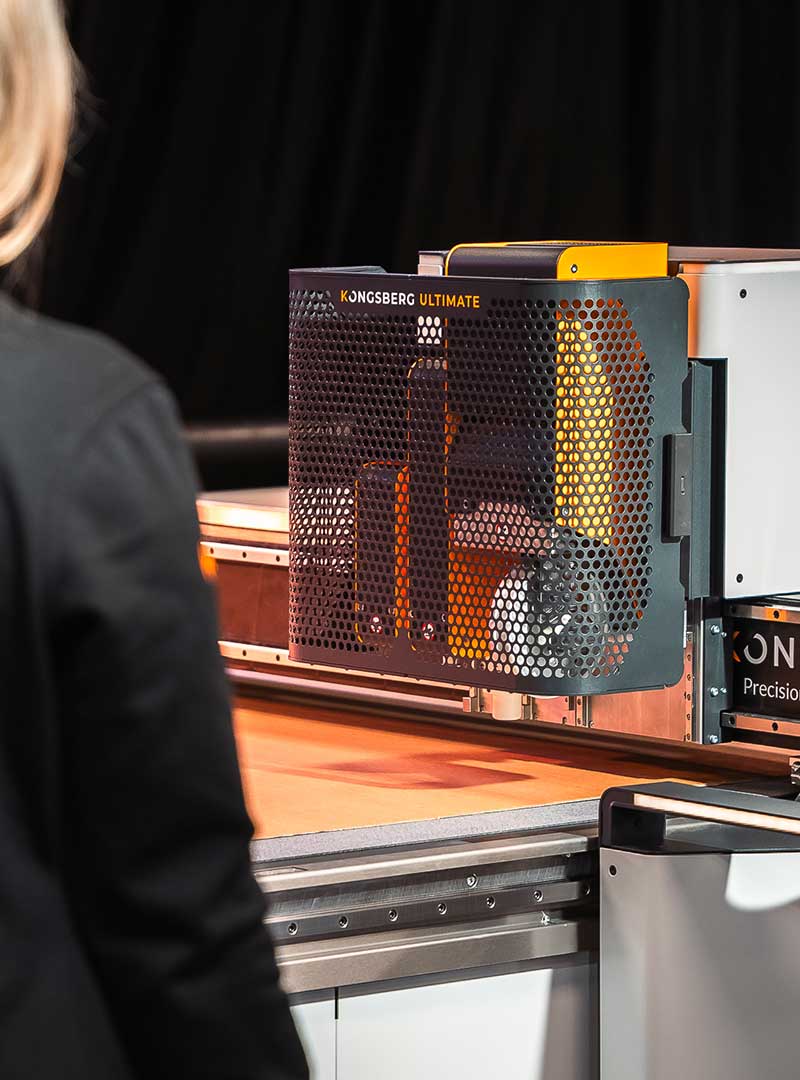

The Kongsberg SmartZone™ safety solution is an innovative proximity detection system. It blends safety and efficiency seamlessly.

The Kongsberg Ultimate is designed to offer an unmatched and seamless experience for every operator. The intuitive iPC 3.0 interface, complemented by easily accessible buttons, simplifies all operator tasks.

The Kongsberg Ultimate is designed with the future in mind. Its modularity ensures it's always relevant, adapting to changing business needs.

Want to know how? In this free guide we outline the 7 ways the Kongsberg Ultimate brings quicker ROI, delivers unparalleled productivity, boosts profits and is safer on the shop floor.

The Kongsberg Ultimate is configured to guarantee continuous production on corrugated and display jobs. With dedicated tool positions for creasing, cutting and perforating, there’s no need to halt production to change out tools.

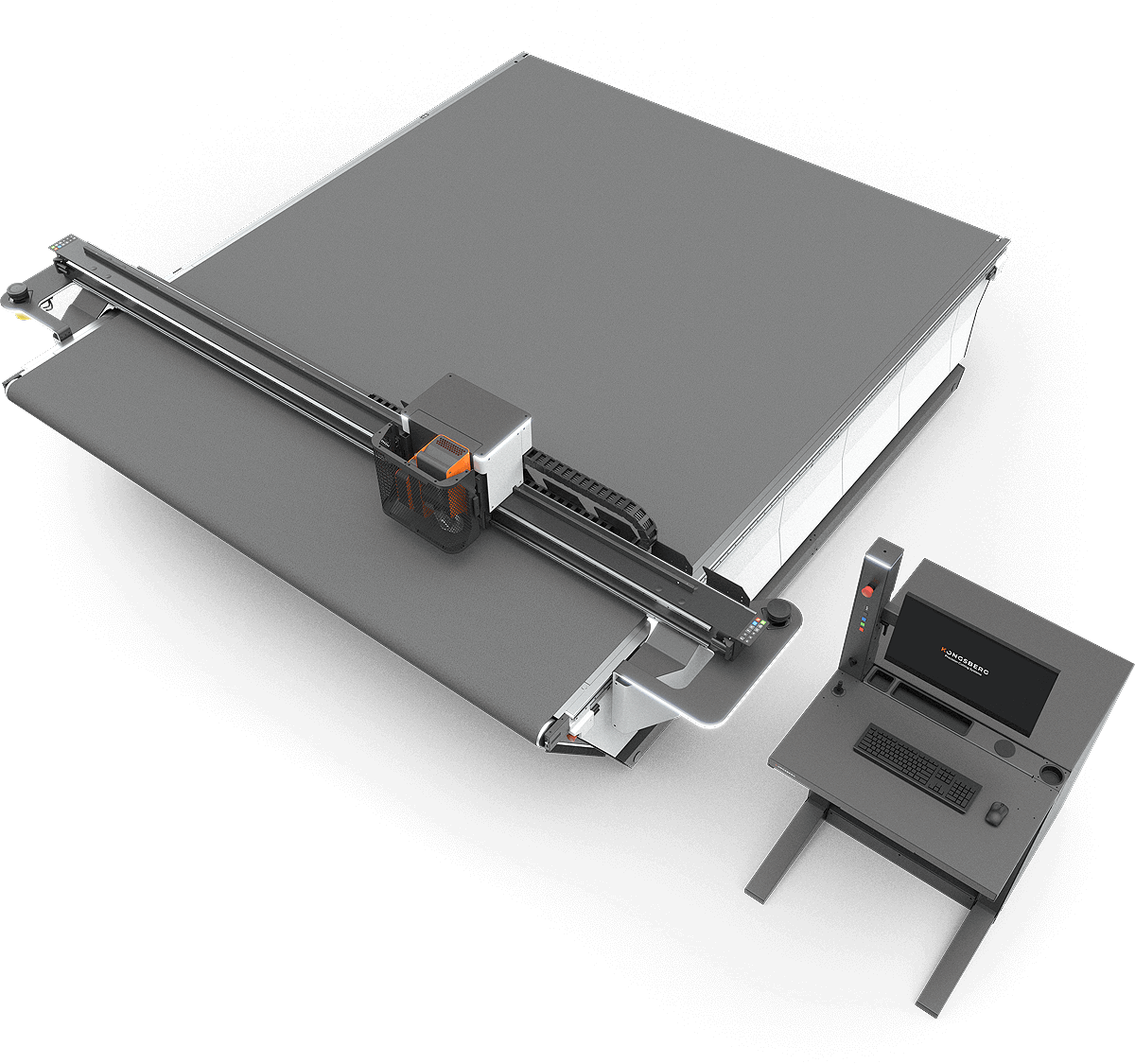

The Kongsberg Ultimate cutting table is modular, it grows with your needs: from manual, to semi-automated with a Feeder & Stacker, right up to the pinnacle of automated production with the Robotic Material Handler.

Kongsberg Precision Cutting Systems has a global network of service engineers, offering peace of mind and maximal uptime!

... you’re looking to execute your vision and values to drive the success of your company. The Kongsberg Ultimate directly supports this by maximizing ROI, maintaining consistent uptime, and offering a modular configuration.

... the Kongsberg Ultimate stands out by its jaw-dropping acceleration of up to 2.7G and over 165 m/min speeds which bring peak productivity. Quick installations, minimal maintenance, a robust support system, and precision-driven features make the Kongsberg Ultimate an invaluable asset for any production floor.

... the Kongsberg Ultimate is a game-changer: safety is a priority, intuitive user interfaces make complex tasks easy and the precision is stellar, making you the person that produces perfect jobs, over and over.

|

|

24 | 44 | 64 | 66 |

| Work area |

1680 x 3200 mm 66 x 126 in. |

2210 x 3200 mm 87 x 126 in. |

3210 x 3200 mm 126.4 x 126 in. |

3210 x 4800 mm 126.4 x 189 in. |

| Work area, MultiZone |

1680 x 1450 mm 66 x 57 in. |

2210 x 1450 mm* 87 x 57 in.* |

3210 x 1600 mm 126.4 x 63 in. |

3210 x 2210 mm 126.4 x 87 in. |

| Max. material size w/o conveyor feed |

1780 x 3920 mm 70 x 154.3 in. |

2310 x 3920 mm 90.9 x 154.3 in. |

3330 x 3920 mm 131 x 154.3 in. |

3330 x 5520 mm 131 x 217.3 in. |

| Max. material size w/ conveyor feed |

1680 mm 66 in. |

2210 mm 87 in. |

3210 mm 126.4 in. |

3210 mm 126.4 in. |

| Max. material thickness |

30 mm 1.18 in. |

|||

| Traverse clearance, excl. underlay |

50 mm 1.97 in. |

|||

| Feeder & Stacker production, simultaneous mode |

n/a |

n/a |

3200 x 1600 mm 126 x 63 in. |

3200 x 2200 mm 126 x 86.6 in. |

| Feeder & Stacker production, sequential mode |

n/a |

n/a |

3200 x 2200 mm 126 x 86.6 in. |

3200 x 2200 mm 126 x 86.6 in. |

| Machine dimensions, excl. workstation |

2880 x 3980 mm 113.4 x 156.7 in. |

3410 x 3980 mm 134.3 x 156.7 in. |

4430 x 3980 mm 174.4 x 156.7 in. |

4430 x 5580 mm 174.4 x 156.7 in. |

| Machine height (table-top) |

1415 (875) mm 55.7 (34.5) in. |

|||

| Vacuum zones |

8 |

|||

| Workstation dimensions |

900 x 804 mm 35.4 x 31.7 in. |

| Workstation height (work-top) |

1704 (940-1040) mm 67 (37-41) in. |

| Max. linear speed (XY) |

167.5 m/min (2.8 m/sec) 110 IPS |

|||

| Max. linear acceleration (XY) |

27 m/s2 - 1059 in/s2 2.74G |

26 m/s2 – 1023 in/s2 2.65G |

24.5 m/s2 – 965 in/s2 2.5G |

24.5 m/s2 – 965 in/s2 2.5G |

| Max. tooling speed (Z) |

Heavy-duty tools: 15 m/min - 0.25 m/sec - 9.8 IPS Fast tools: 45 m/min - 0.75 m/sec - 29.5 IPS |

|||

| Max. tooling acceleration (Z) |

Heavy-duty tools: 8 m/s2 - 315 in/s2 - 0.8G Fast tools: 22 m/s2 - 866 in/s2 - 2.22G |

|||

* Optional equal-zone table-top available for the Ultimate 44: 2210 x 1600 mm (87 x 126 in.)

Interested in experiencing the future of corrugated cutting? Get in touch with us and have a chat with our industry experts.