Foam & Foam Core Board

Kongsberg cutting tables offer powerful tools for excellent results on foam and foam core board.

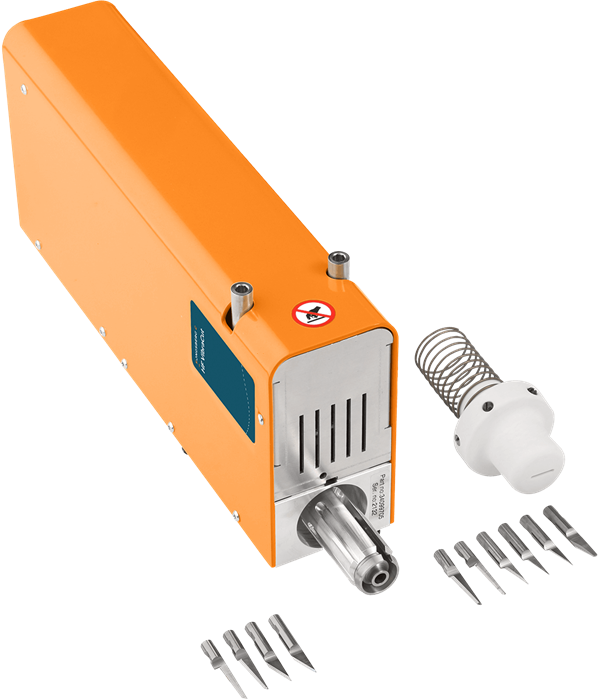

The Foam Head is a heavy duty tool made for cutting a large range of foam materials up to 86 mm (3 ¾") thickness. These types of foam are typically used in the protective packaging industry.

The FoamHead is a reciprocating knife designed with characteristics optimal for low density porous material. It runs at a frequency of 4,800 strokes per minute and at amplitude of 4 mm. The great Z-axis control gives an advantage when cutting foam because it ensures consistent partial cut, which is very important with many foam designs.

We know that the thickness, hardness or texture of some materials can make it challenging to achieve the highest quality finish. This can result in imperfect cuts, damaged equipment, and wasted resources.

Download our handy new guide and discover how with a Kongsberg cutting table you can maximize quality and protect your margins, even when using the most demanding materials.

This tool is suitable for single and double wall corrugated board and other light-duty fibrous materials, such as corrugated board, soft foam board and corrugated plastic.

It runs at a frequency of 6,000 Strokes per minute and with an amplitude of 0.3 mm.These properties, along with a powerful motor, enable cutting at full table speed with good quality materials.

The High-frequency VibraCut Knife Tool is a high-frequency reciprocating knife tool for cutting a lot of different materials, such as corrugated board with high-recycled content, soft foam board, corrugated plastic and fluted core board.

It runs at a frequency of 12,000 strokes per minute and amplitude of 1.2 mm. This enable cutting of heavily recycled board at efficient speed. A floating foot is used to reduce material tear and to keep the material down.

The Bevel Knife tool is suitable for a 45˚ slanted cut for v-notching or single through cutting.

Perfect for V-notching of folding lines in display board materials. The purpose is to create an exact, sharp 90˚ fold in materials that cannot be folded with conventional crease tooling.

Free guide

Using a Kongsberg cutting table allows you to extend on your offerings and protect your margins.