Cutting Flexographic Plates

Kongsberg X Edge cutting tables bring tangible benefits to the production of digital flexo plates.

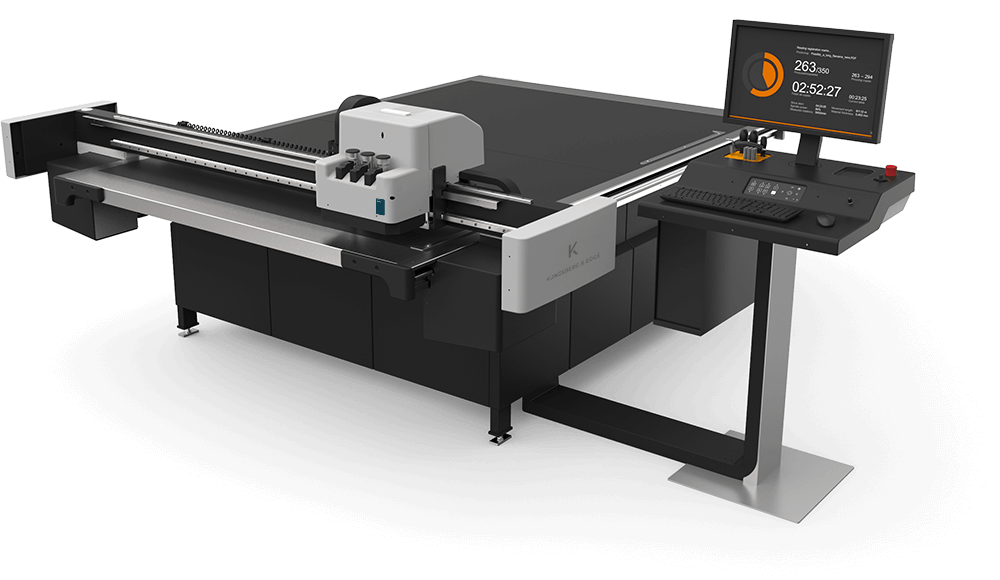

The Kongsberg X Edge CAD table is the ideal start of any digital cutting journey. The tried and tested Kongsberg recipe of productivity and flexibility combined with best in class reliability – no compromise.

Step up your productivity by automating manual steps with the Kongsberg X Edge cutting table.

| X20 Edge Production For flexo plates up to 1200 x 900 mm (48 x 35 in.) |

X22 Edge Production For flexo plates up to 1067 x 1524 mm (42 x 60 in.) |

||

| Work area, all tools | 1680 x 1270 66 x 50 |

1680 x 2190 66 x 86 |

mm in. |

| Max. material size | 1740 x 1750 68 x 69 |

1740 x 2570 68 x 101 |

mm in. |

| Max. speed | 30 500 20 |

m/min mm/sec IPS |

|

| Position accuracy |

200 .0078 |

μm in. |

|

We know that the thickness, hardness or texture of some materials can make it challenging to achieve the highest quality finish. This can result in imperfect cuts, damaged equipment, and wasted resources.

Download our handy new guide and discover how with a Kongsberg cutting table you can maximize quality and protect your margins, even when using the most demanding materials.

The FlexiHead combines highly accurate cutting with power and robustness even for the most complex and compact materials.

The FlexiHead comes with a lockable foot to prevent the measuring foot from touching the sensitive flexo plates.

The Bevel Knife Tool for flexo plates is suitable for a 45˚ slanted cut for v-notching or single through cutting. The tool enables high performance cutting of bevelled edges in flexographic plates using the special developed knife blade BLD-SF212.

The Rigid Material Knife Tool is a static knife tool suitable for a wide range of materials at high speed. It’s also perfect to quickly cut corrugated boxes to ship flexo plates.

The KissCut Knife Tool can be used to cut information (such as patch ID) in the very top layer of the flexographic plate.

The Fiber Tip Pen Tool option provides drawing capabilities on materials such as clear vinyl or flexographic plates, which normally cannot be marked with ballpoint or liquid ink pens. Use the Fiber Tip Pen Tool to identify the different patches of flexo so mounting them later on becomes a breeze.

This tool insert consists of an electric drill—which fits in the FlexiHead—and a special drill bit (6.35 mm (1/4 in.) in diameter). Drill power is supplied through the connector for reciprocating tools on the tool head. The drilling tool is provided with an internal motor, which spins the drill bit up to 1,000 RPM.

Free guide

Using a Kongsberg cutting table allows you to extend on your offerings and protect your margins.