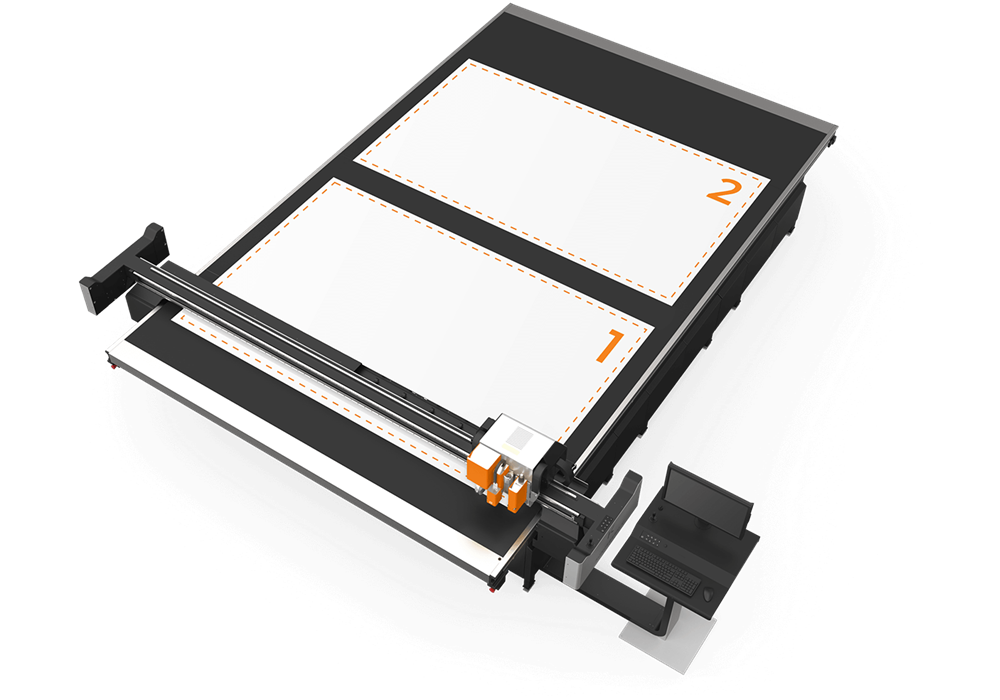

Kongsberg C – Powering 24/7 display production

The Kongsberg C is purpose-built to handle the high expectations of modern display production.

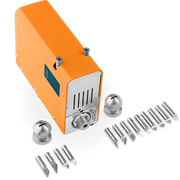

From fast turnarounds to working with a wide mix of substrates, it delivers the performance, precision and flexibility you need to stay ahead. With ultra-stable engineering and a powerful tool system, the C helps you manage tight schedules, varied job sizes and last-minute edits with ease.

Designed for around-the-clock output, it runs reliably in fully automated workflows, making it the go-to choice for non-stop, high-volume production without compromise.