Cardboard

The Kongsberg cutting tables have dedicated tools to cut, v-notch, drill and crease cardboard materials (papercore board, display board, grey board, solid board, ...)

The High-frequency VibraCut Knife Tool is a high-frequency reciprocating knife tool for cutting a lot of different materials, such as corrugated board with high-recycled content, soft foam board, corrugated plastic and fluted core board.

It runs at a frequency of 12,000 strokes per minute and amplitude of 1.2 mm. These properties, along with a powerful motor, enable cutting of heavily recycled board at efficient speed.

For 45° V-notch cutting in triple wall corrugated, corrugated plastic and fluted core board. Its application is to make a 90° partially cut V-notch for folding functionality or a through-cut leaving a slanted cutting edge.

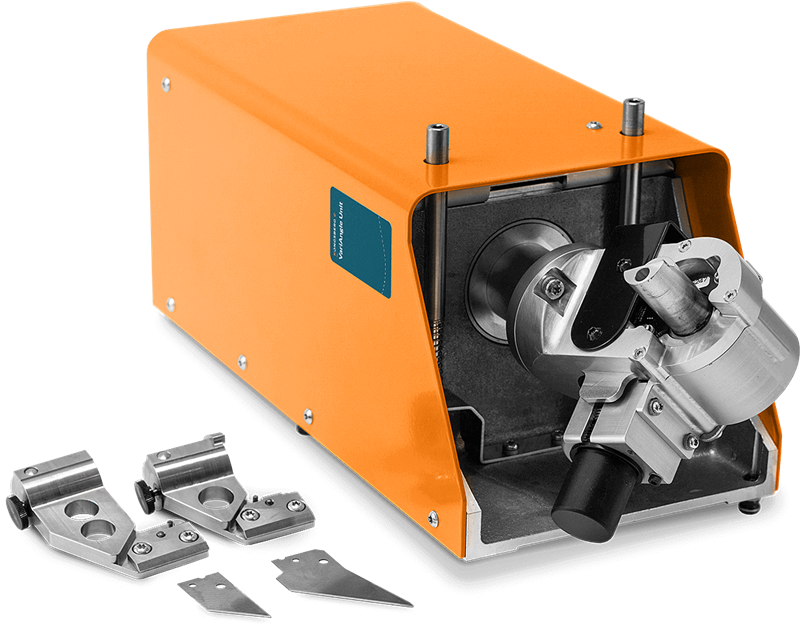

The VariAngle is a unique tool that automatically changes the cutting angle of the knife in increments of 0.5 degrees.

With conventional V-notch solutions operators have to stop the production to change the tools or the blade angle. The new VariAngle Tool lets you run the cutting table without the need of interventions during the production.

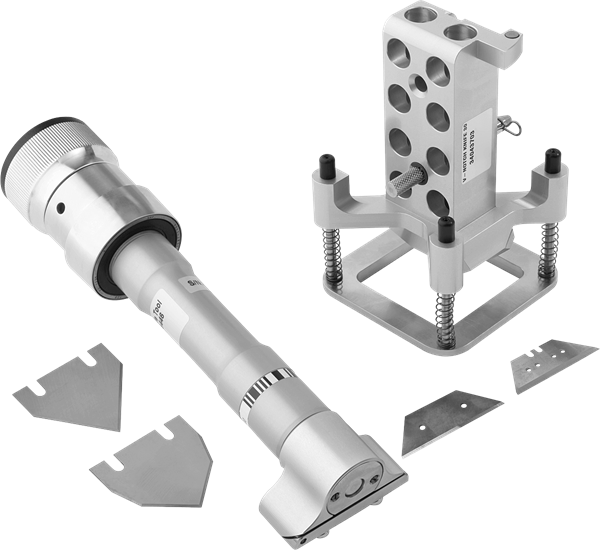

The Drill Tool is aimed at light-duty drilling in materials such as fluted core board, Honeycomb, soft foam board and triple wall corrugated. Typically, a hole is drilled for the purpose of using special screws to attach shelves or other details in connection with displays, or as a way to close or join panels in heavy-duty shipping containers.

The drilling function is provided by the head rotation control, which spins the tool at about 1,000 RPM.

We know that the thickness, hardness or texture of some materials can make it challenging to achieve the highest quality finish. This can result in imperfect cuts, damaged equipment, and wasted resources.

Download our handy new guide and discover how with a Kongsberg cutting table you can maximize quality and protect your margins, even when using the most demanding materials.

The Bevel Knife tool is suitable for a 45˚ slanted cut for v-notching or single through cutting.

The Bevel Knife Tool for Solid Board is developed for V-notching of folding lines in solid board (grey board) material using the special developed knife blade BLD-SF245. The purpose is to create an exact, sharp 90˚ fold in materials that cannot be folded with conventional crease tooling.

The CorruSpeed Tool is developed for cutting corrugated board at high speeds without oscillating.

The tool brings significant time savings on many corrugated boards, even boards with recycled content. The CorruSpeed Tool works with corrugated board up to double wall BC flutes (7 mm).

The CorruSpeed uses a crushing cup, which – combined with controlled down pressure - makes it possible to use a drag knife without tearing or cracking the liner.

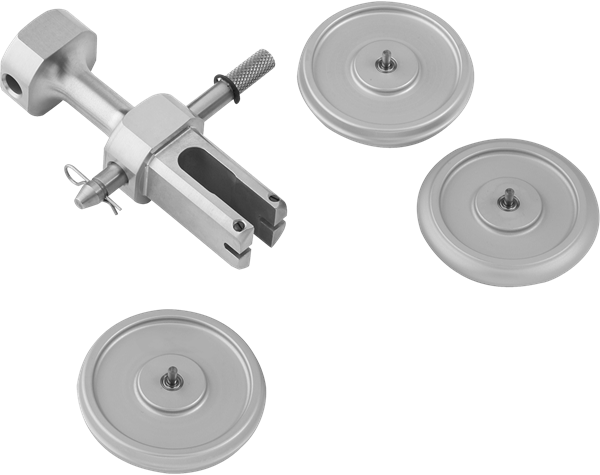

The 60 mm Crease Wheel offers the possibility to crease most corrugated thicknesses.

The medium-size wheels also allow for creasing with a higher pressure without cracking the liner, and with a limited over-crease.

The optional 60 mm Perforation Wheel pack offers the possibility to produce tear perforations at high speeds for corrugated board up to C flute (4 mm).

Do you want more information? Would you like to schedule a demo? Just feel like chatting?

We are here for you! Just leave your contact info below and we'll get back to you.