Breakthrough Automation

A range of impressive innovations will boost the performance of digital finishing operations to industrial levels.

Want to discover 5 ways to make money with a Kongsberg cutting table?

Download this free guide today!

A range of impressive innovations will boost the performance of digital finishing operations to industrial levels.

Want to discover 5 ways to make money with a Kongsberg cutting table?

Download this free guide today!

Kongsberg cutting tables can be combined with a robotics setup. The robotic arm loads new and offloads finished material, in perfect sync with the table.

The robotics arm uses the tables’ multi-zone functionality. In a production environment specialized for point of purchase materials and packaging, the robotics setup reduces load time, which is one of the more time-consuming off-line tasks. Production becomes much faster.

Edmont Perrier, CEO, CartonéoOur new press has enabled us to win several key contracts, which is why we also added the integrated production solution (Kongsberg C66 and robotics) to complete the work to a high standard. With both, we are now very busy and competitive in the market for short run production of display materials.

The Kongsberg Automate board feeder and stacker is the perfect way to increase productivity and give your business a competitive edge. It’s an easy to use pallet-to-pallet solution. It feeds corrugated, paper core boards and plastics quickly and accurately from pallet with 2 feed cycles per minute in a continuous material flow. There are no delays loading and unloading boards from the table, so the table is utilized optimally.

The feeder and stacker are developed for the Kongsberg X and Kongsberg C tables. The board feeder (i-BF) and stacker (i-MF) can be purchased separately. An optional roll feeding unit and extension tables are also available.

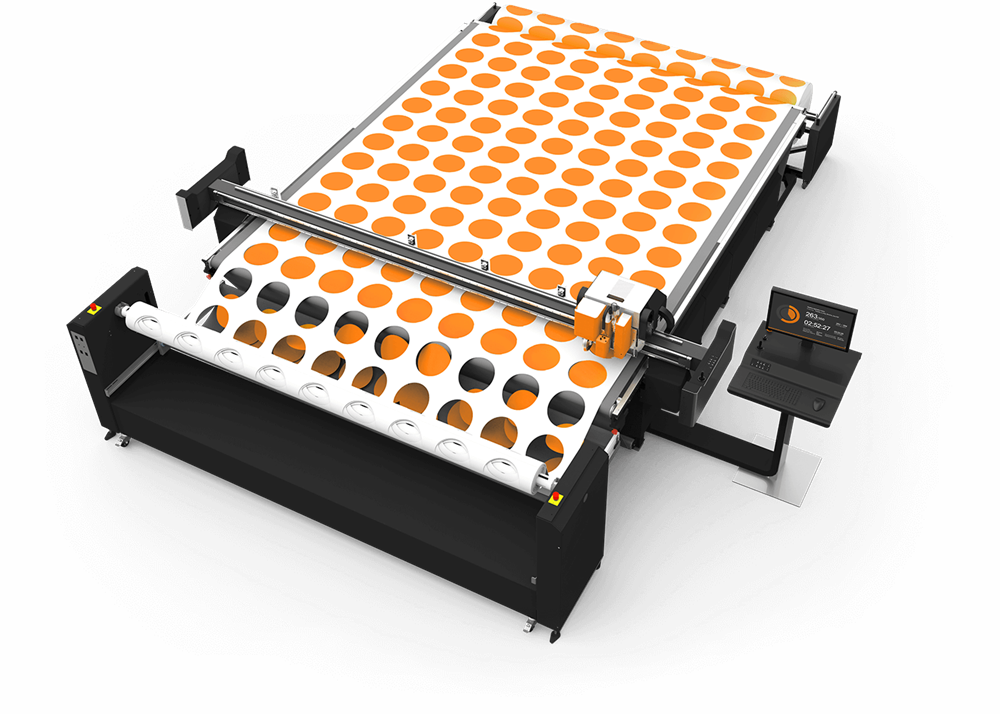

The Kongsberg motorized roll feeder increases productivity and reduces operator time for production of wide-format, flexible materials with the Kongsberg C60 and 64 cutting tables.

The Kongsberg Take Up Unit for flexible materials makes roll to roll workflows easier. The unit makes finishing digitally printed jobs on rolls, and collecting waste, very straightforward.

The Take Up Unit is simple to install for any Kongsberg table equipped with a conveyor feed system. The unit is hassle-free to operate and can easily be moved away when it’s not needed.

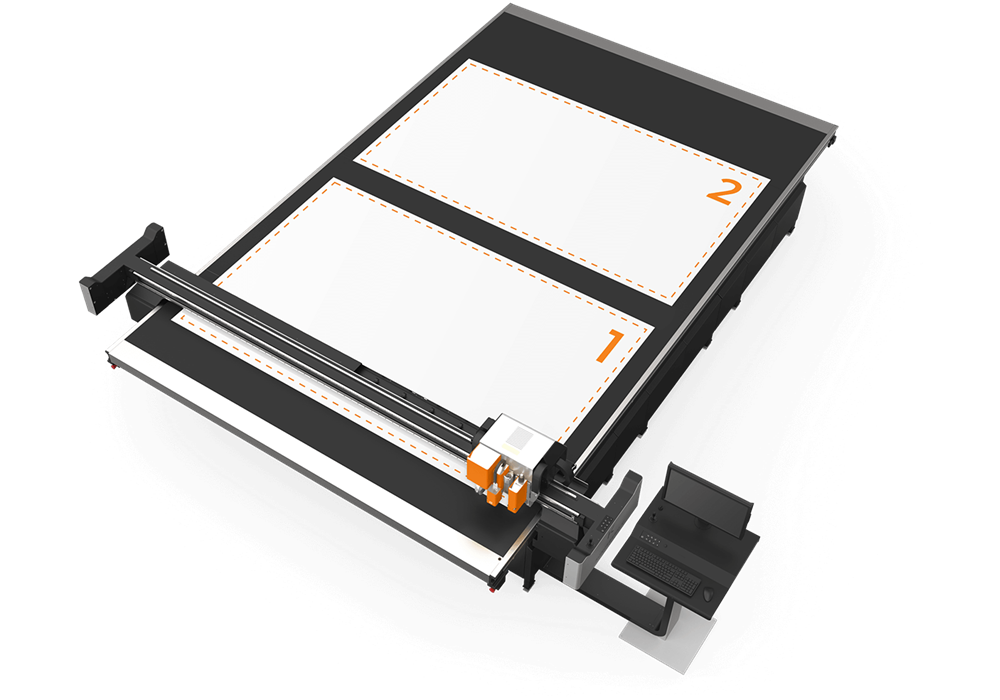

Kongsberg tables are able to work with two work zones independently: multi-zone finishing.

This is particularly useful with the larger Kongsberg tables. While one zone of the table is in action, an operator can set up the other zone by clearing the finished piece and loading a new sheet. While the operator works and prepares one zone, the machine works at the other zone.

Do you want more information? Would you like to schedule a demo? Just feel like chatting?

We are here for you! Just leave your contact info below and we'll get back to you.